Unveiling the Superiority of Qiming Casting Custom Wear Parts

The selection of wear parts can make all the difference in the fast-paced world of heavy industry, where equipment is subject to relentless demands and downtime is not an option. That’s where Qiming Casting steps in.

As a leading foundry in China, we specialize in crafting custom wear parts that not only meet but exceed the expectations of our clients across diverse sectors such as mining, quarrying, cement, metal recycling, and coal.

In this blog post, we’re thrilled to unveil the superiority of Qiming Casting custom wear parts. From our unwavering commitment to quality to our innovative materials and technologies, we’ll delve into what sets us apart in the competitive landscape of wear-resistant materials.

Join us on this journey as we explore the key factors that make Qiming Casting a trusted partner for industries seeking optimal performance, durability, and reliability in their wear parts. Whether you’re a mining operator grappling with abrasive conditions or a cement plant manager navigating high-temperature environments, we have the expertise and solutions to elevate your operations to new heights.

Superiority of Qiming Casting Custom Wear Parts

Exceptional Quality Standards

One of the cornerstones of our success at Qiming Casting is our unwavering commitment to quality. We understand that our clients rely on our products to withstand harsh operating conditions and deliver optimal performance. That’s why we adhere to stringent quality control measures at every stage of the manufacturing process.

From the selection of premium raw materials to the precision casting techniques employed by our skilled craftsmen, we ensure that each wear part meets our high-quality standards. Our products undergo rigorous testing to guarantee durability, strength, and resistance to abrasion, impact, and wear.

Diverse Range of Products

At Qiming Casting, we offer a comprehensive range of custom wear parts tailored to the specific needs of different industries. Whether it’s crusher wear parts, mill liners, shredder wear parts, apron feeder pans, or electric rope shovel parts, we have you covered. Our extensive product catalog includes components for various types of machinery, including cone crushers, jaw crushers, impact crushers, gyratory crushers, hammer mills, and VSI crushers.

We understand that no two applications are alike, which is why we provide customization options to suit unique requirements. Our team works closely with clients to develop bespoke solutions that optimize performance and prolong equipment lifespan.

Innovative Materials and Technologies

What truly sets Qiming Casting apart is our continuous pursuit of innovation. We stay at the forefront of the industry by investing in research and development to discover new materials and technologies that enhance the performance of our wear parts.

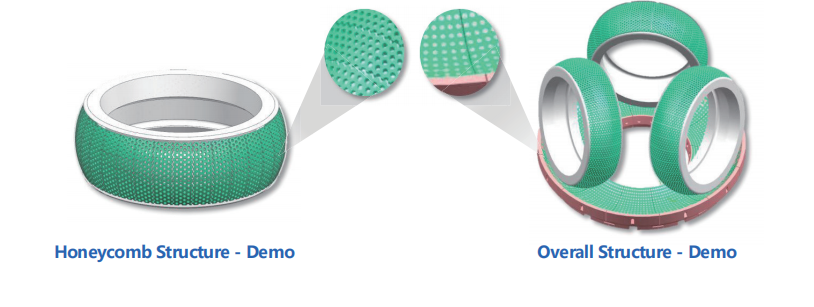

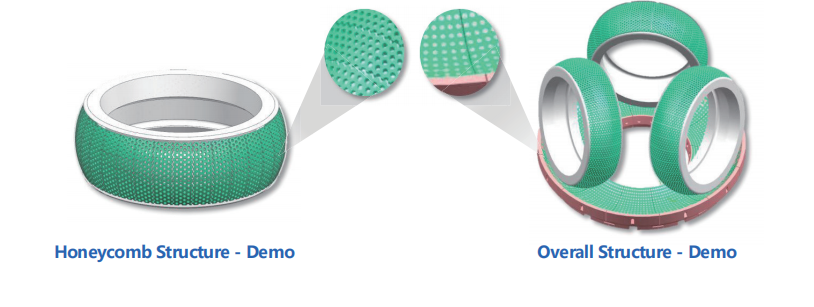

Our materials range from traditional options like manganese steel, chromium steel, and alloy steel to specialized alternatives such as TIC inlay wear parts and ceramic inserts wear parts. These advanced materials offer superior resistance to wear, corrosion, and impact, ensuring prolonged service life and reduced maintenance costs for our clients.

Furthermore, we leverage cutting-edge manufacturing techniques, including ceramic inlay and TIC inlay processes, to achieve optimal wear resistance and performance. By harnessing the power of technology, we deliver wear parts that surpass expectations and provide unparalleled value to our customers.

Tailored Solutions for Every Industry

At Qiming Casting, we recognize that each industry has its own unique challenges and requirements. That’s why we take a personalized approach to meet the diverse needs of our clients across different sectors.

Whether it’s the rugged demands of the mining industry, the high-temperature environments of cement plants, or the abrasive conditions of metal recycling facilities, we have the expertise to develop tailored solutions that withstand the toughest conditions. Our team of engineers works closely with clients to understand their specific applications and recommend the most suitable wear parts for optimal performance and productivity.

Certified Quality Assurance

Our commitment to quality is further underscored by our certifications and accreditations. Qiming Casting products adhere to international quality standards and undergo rigorous testing to ensure compliance and reliability.

We are proud to have earned ISO9001, CE, and GOST certifications, reflecting our dedication to quality management and customer satisfaction. These certifications serve as a testament to our unwavering commitment to excellence and provide our clients with peace of mind knowing that they are investing in premium-quality wear parts.

Elevating Industry Standards With Qiming Casting Custom Wear Parts

Thus, Qiming Casting Custom Wear Parts stand out as the preferred choice for industries seeking superior performance, durability, and reliability. With our unwavering commitment to quality, diverse range of products, innovative materials and technologies, tailored solutions, and certified quality assurance, we continue to set the benchmark for excellence in the foundry industry.

Whether you’re in mining, quarrying, cement, metal recycling, or coal, you can trust Qiming Casting to deliver wear parts that exceed expectations and maximize the lifespan of your equipment. Experience the superiority of Qiming Casting Custom Wear Parts and elevate your operations to new heights of performance and efficiency.